Plastic-free

Free UK delivery

100% recyclable

Gummed Tape

Minimum order quantity: 144

Gummed tape is plastic-free and roadside recyclable, making it a more sustainable way to seal any paper-based package. Choose from two widths and two weights, and customise to complete a branded parcel.

- Plastic-free

- Roadside recyclable

- 3 colour printing

- Available in 48mm and 72mm

- Available in 70gsm and 90gsm

Have questions? Contact us

Key features

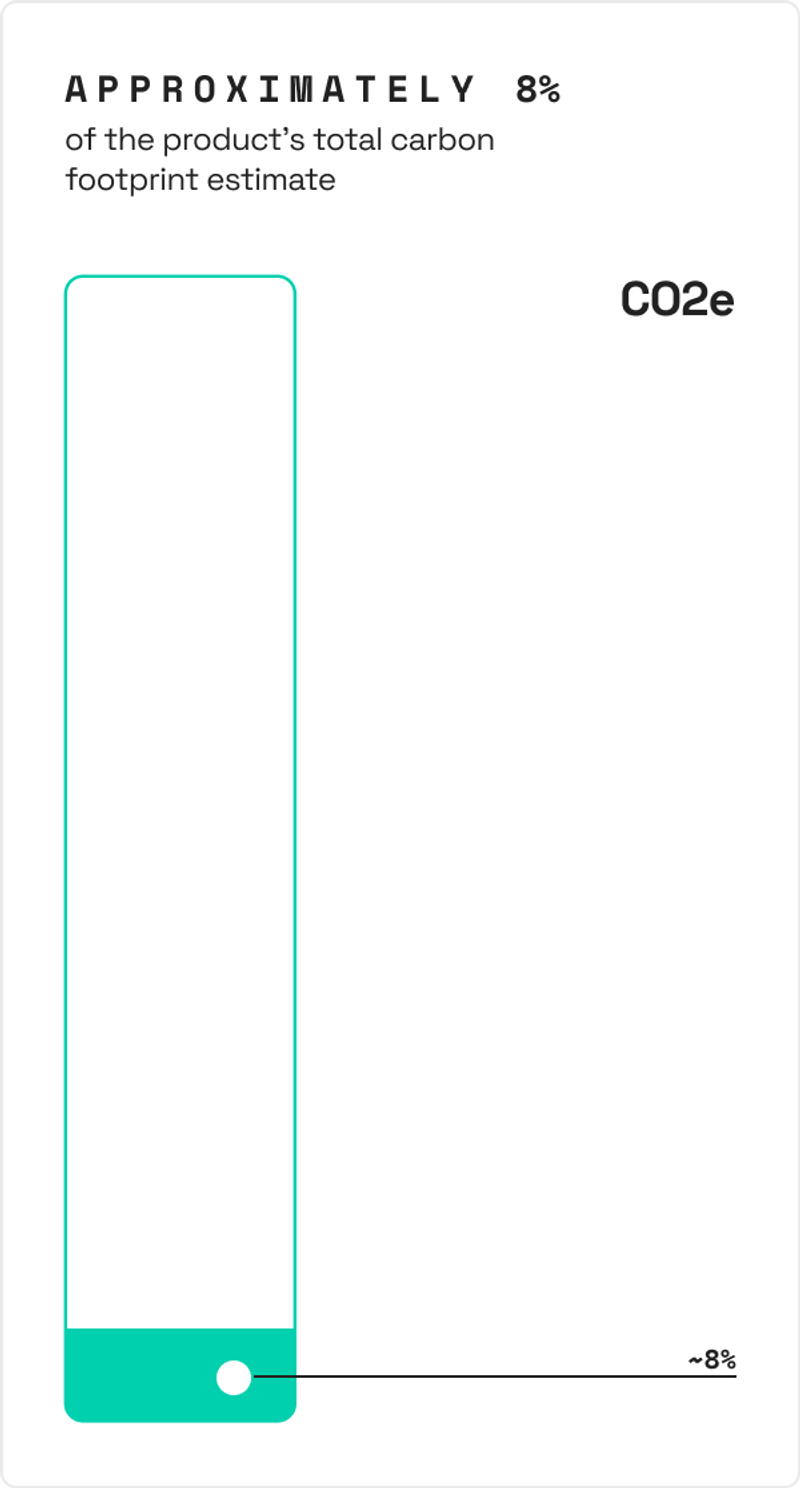

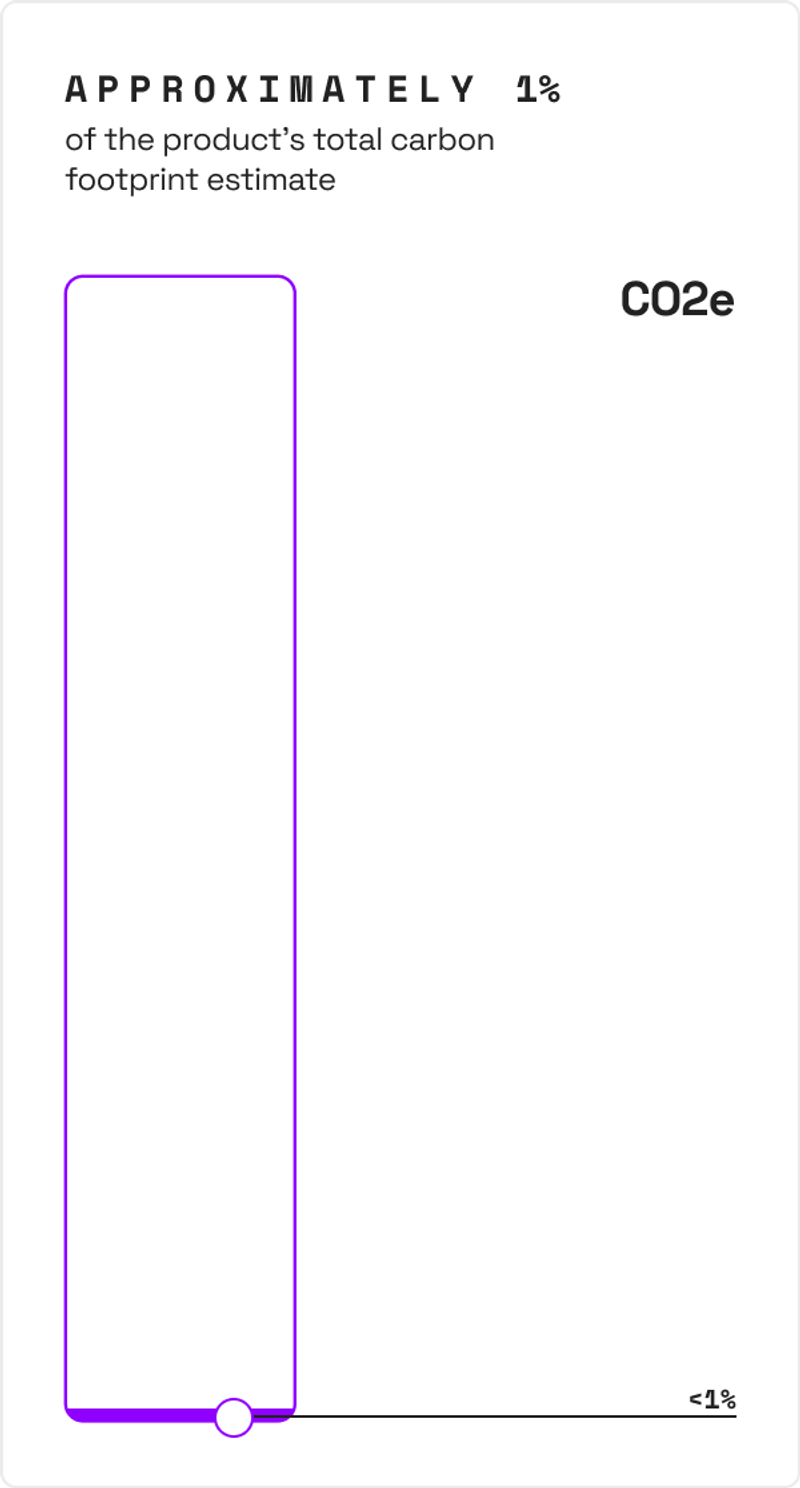

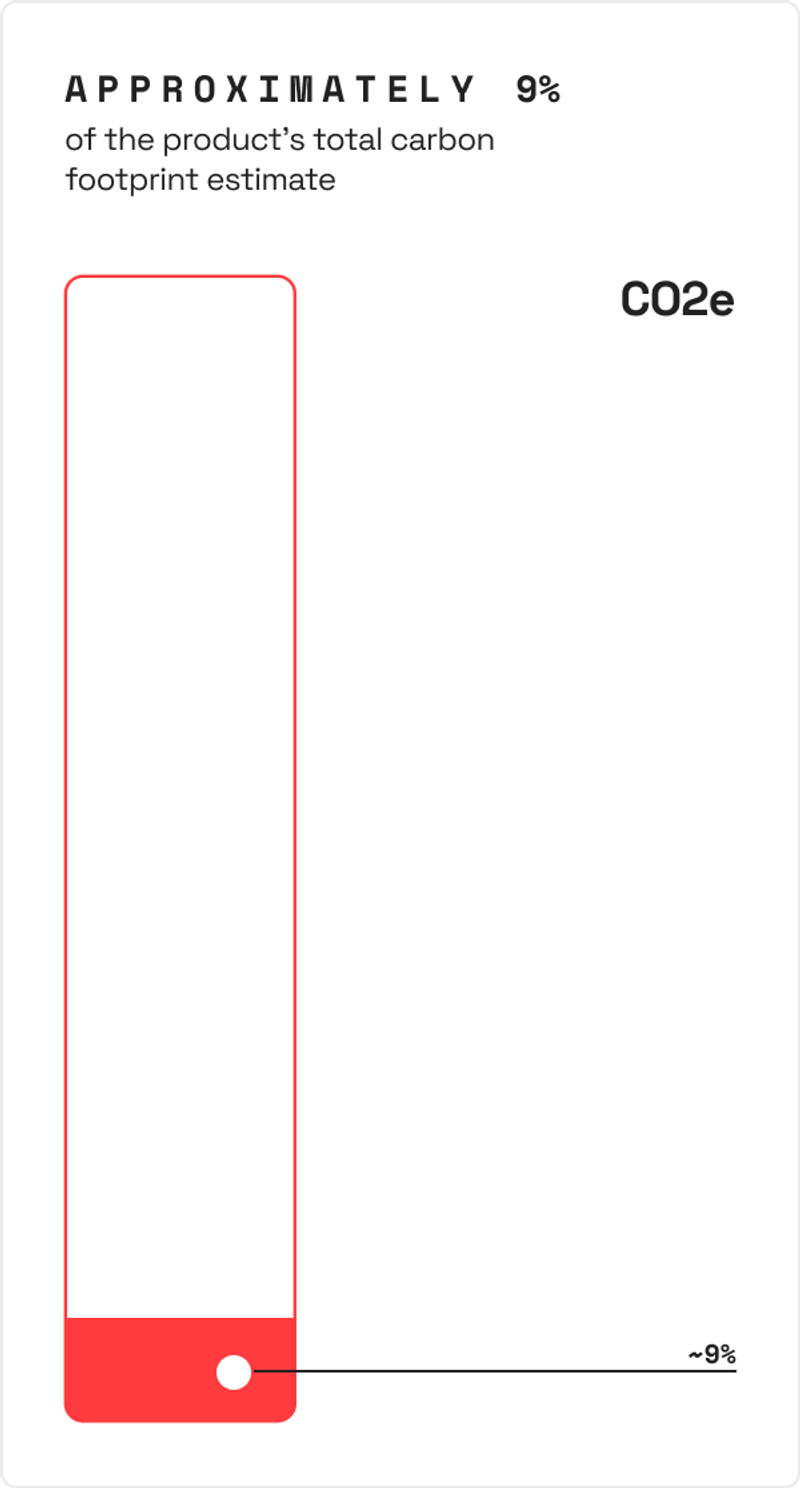

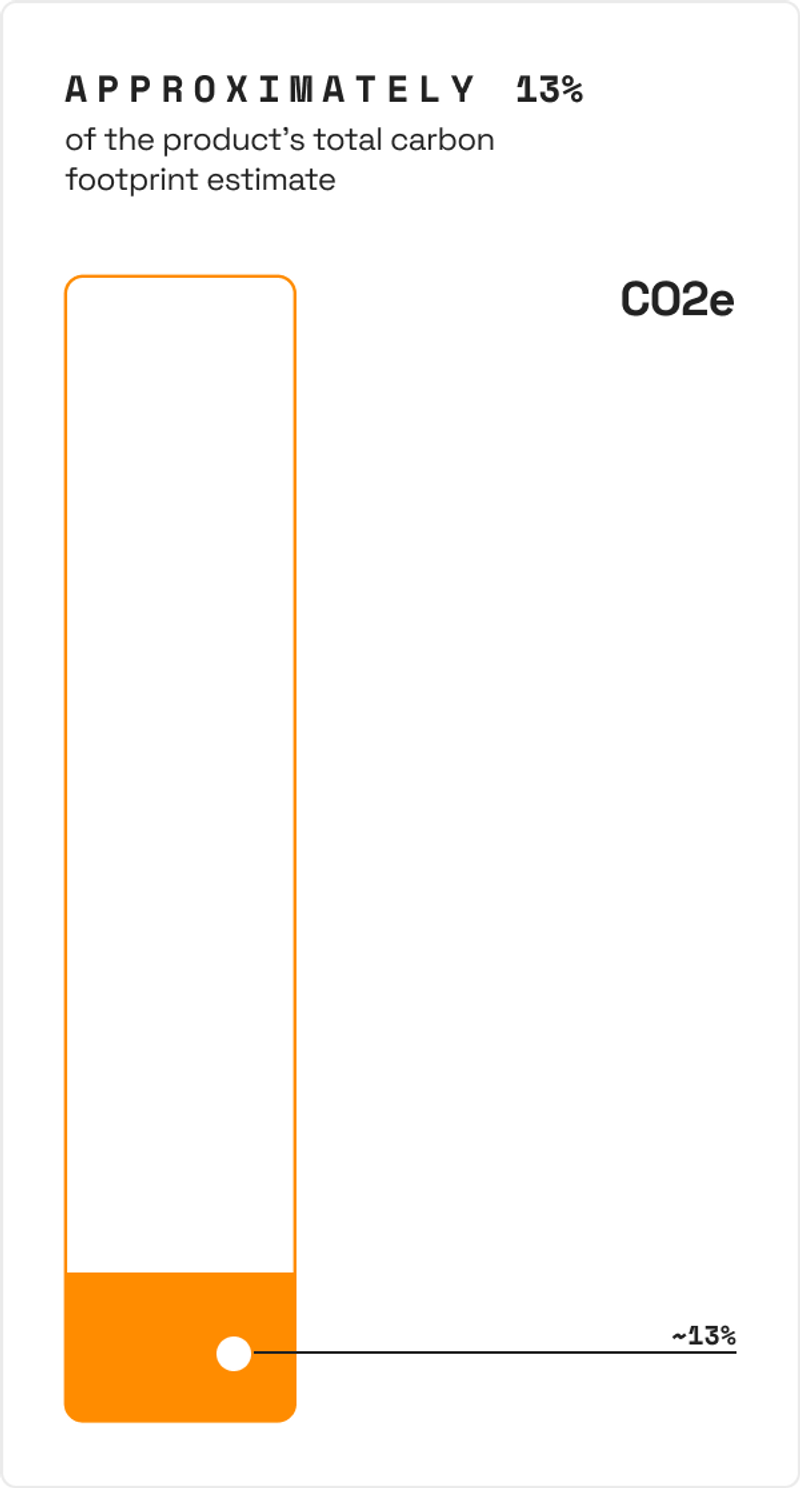

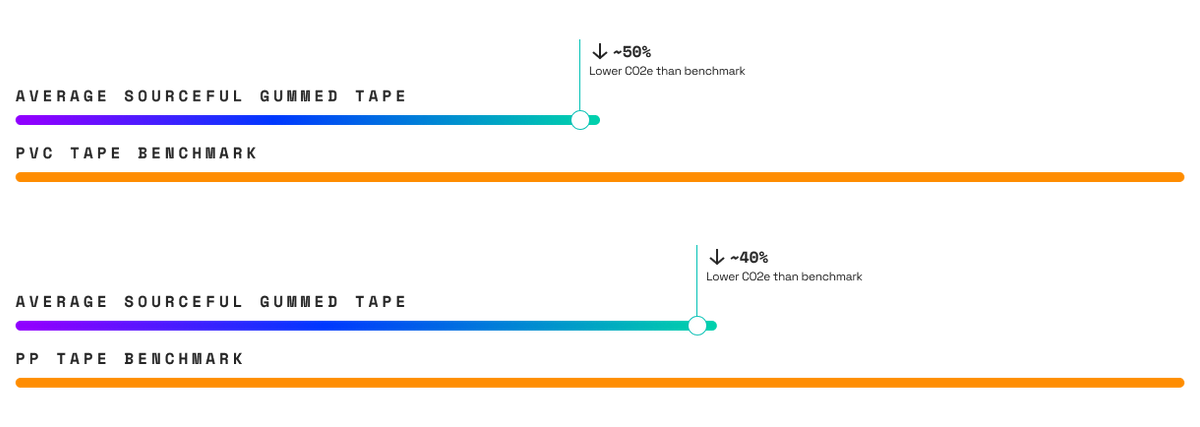

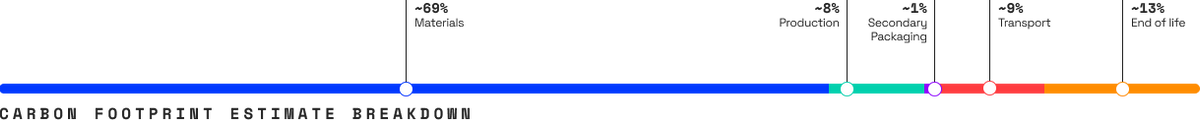

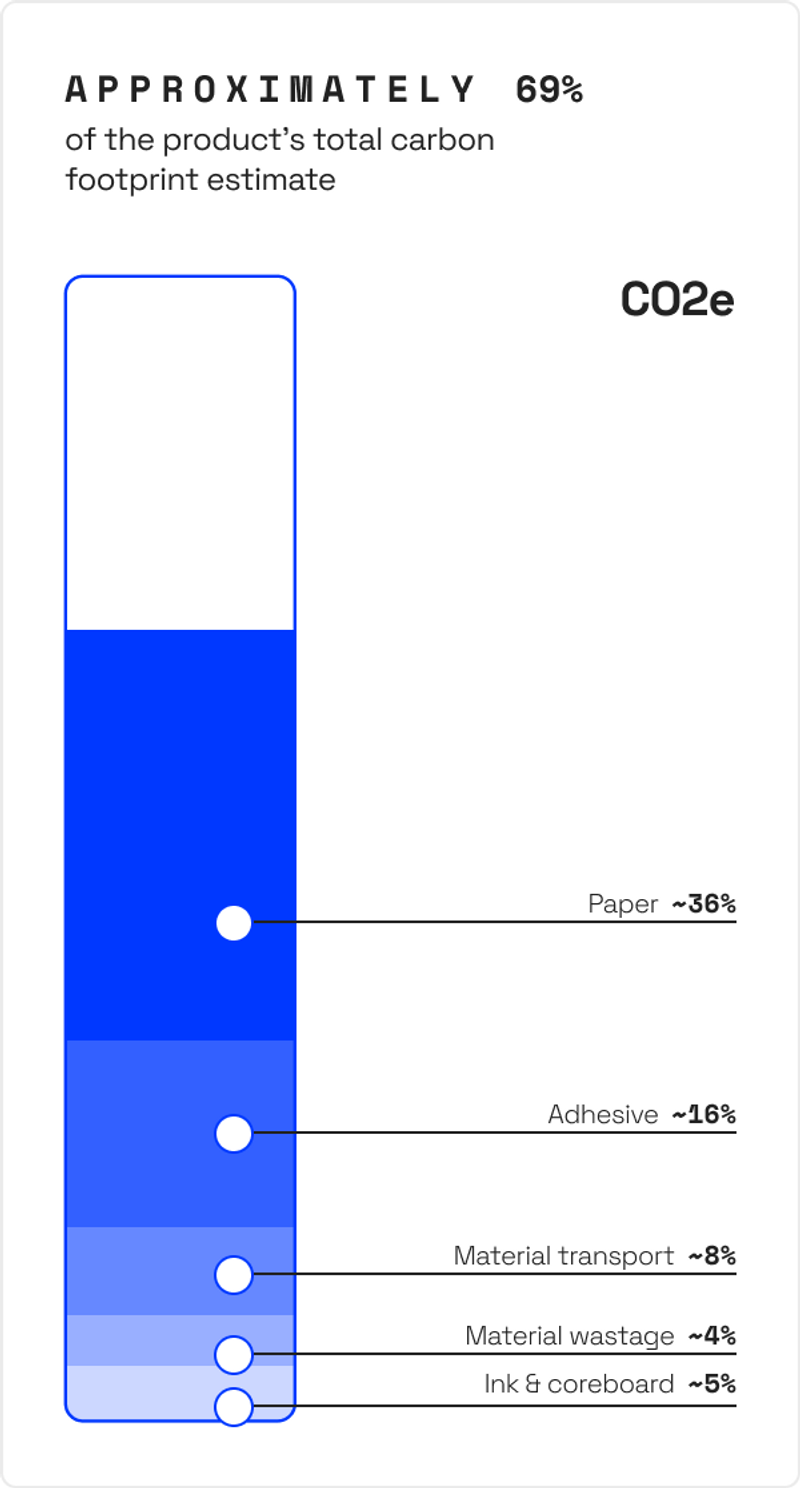

Carbon footprint

See how the carbon footprint of Sourceful’s gummed tape compares to a benchmark product.

Reduce your carbon footprint by up to 50%

-50% CO2e

Switching base material and adhesive from a typical PVC (Polyvinyl chloride) tape could reduce your carbon footprint by up to 50%.

-40% CO2e

Switching base material and adhesive from a typical BOPP (Biaxially Oriented PolyPropylene) tape could reduce your carbon footprint by up to 40%.

Specification

Understand your entire supply chain

- Bk

Brown kraft paper

Unbleached and uncoated paper made from virgin pulp. Brown kraft paper is the most sustainable material for this gummed tape. Ideal for simple, bold designs and after use, it’s 100% recyclable. Bright colours will appear more muted on brown kraft tape. - Wk

White kraft paper

Bleached paper made from virgin pulp. White kraft paper has a higher carbon footprint than brown kraft paper but colours appear much brighter. - 70

70gsm

A durable, standard weight for gummed tape. 70gsm has a smaller carbon footprint than 90gsm as less material is used. - 90

90gsm

90gsm is thicker and stronger than 70gsm but more material is needed to produce it. This increases its cost and carbon footprint. 90gsm is the best option for sealing heavy or wider packages. - 48

48mm

48mm is the industry-standard width for tape. Suitable for the majority of use cases. - 72

72mm

72mm tape is stronger than 48mm but uses more material to produce. Ideal for heavier or wider packages as the tape covers a greater surface area. - Sa

Starch-based adhesive

Made from potato starch. Gummed adhesive needs to be activated by water before it can be applied. This can be done manually or with a tape dispenser. A starch-based adhesive doesn’t affect recyclability. - Si

Solvent-based ink

Solvent-based inks use solvents such as propyl acetate as their primary base. Commonly used for gummed tape as water-based inks are not compatible with the water-activated adhesive. Solvent-based inks offer a high-quality print finish but do have a higher carbon footprint than water or vegetable-based inks. - Cb

Core board

Used for the core of tape rolls. Core board allows tape to be handled, stored, transported and easily used. Core board is 100% recyclable.

Supply chain assurance

A resilient, responsible supply chain